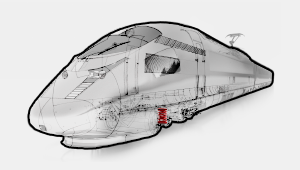

- Coil Springs

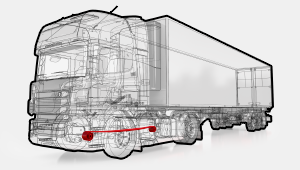

- Leaf Springs

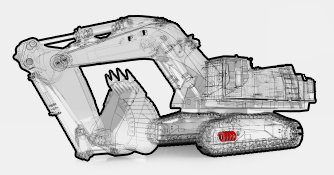

- Parabolic Springs

Coil Springs

The hot-formed compression steel springs are further treated and processed to achieve an optimal strength and toughness ratio of the material, ensuring high operational stability and durability of shape.

Leaf Springs

The springs are further treated and processed to achieve an optimal strength and toughness ratio of the material, ensuring high operational stability of shape.

Parabolic Springs

The springs are further treated and processed to achieve an optimal strength and toughness ratio of the material, ensuring high operational stability of shape.